EXPERTS in Engine Damping Solutions

Extensive knowledge, along with a sense of urgency and pride in quality makes all the difference.

EXPERTS IN

OUR FIELD

high quality manufacturing

Proudly made in America

ABOUT US

Crafting visions, forging dampers

Engine Dampening Solutions (EDS) is a company formed by VFD experts, in order to design, build and rebuild Viscous Fluid Dampers (VFD’s). We have combined expertise of over 100 years of Viscous Damper development. The two partners in the business have over 50 years of damper experience while the plant supervisor has 25 years himself. We have engineering support from Jurgen Depp and Maurizio Macaro (VISCOSYS). Jurgen has been deemed the godfather of viscous damper design and is well published. Together, along with our sister company, L&L Machine, Inc., we are well poised to develop designs, produce dampers and rebuild dampers. Our team is what sets us apart. Extensive knowledge, along with a sense of urgency and pride in quality makes all the difference. Let us help you with your viscous damper needs. Proudly made in America in Northwest Ohio.

Featured Products

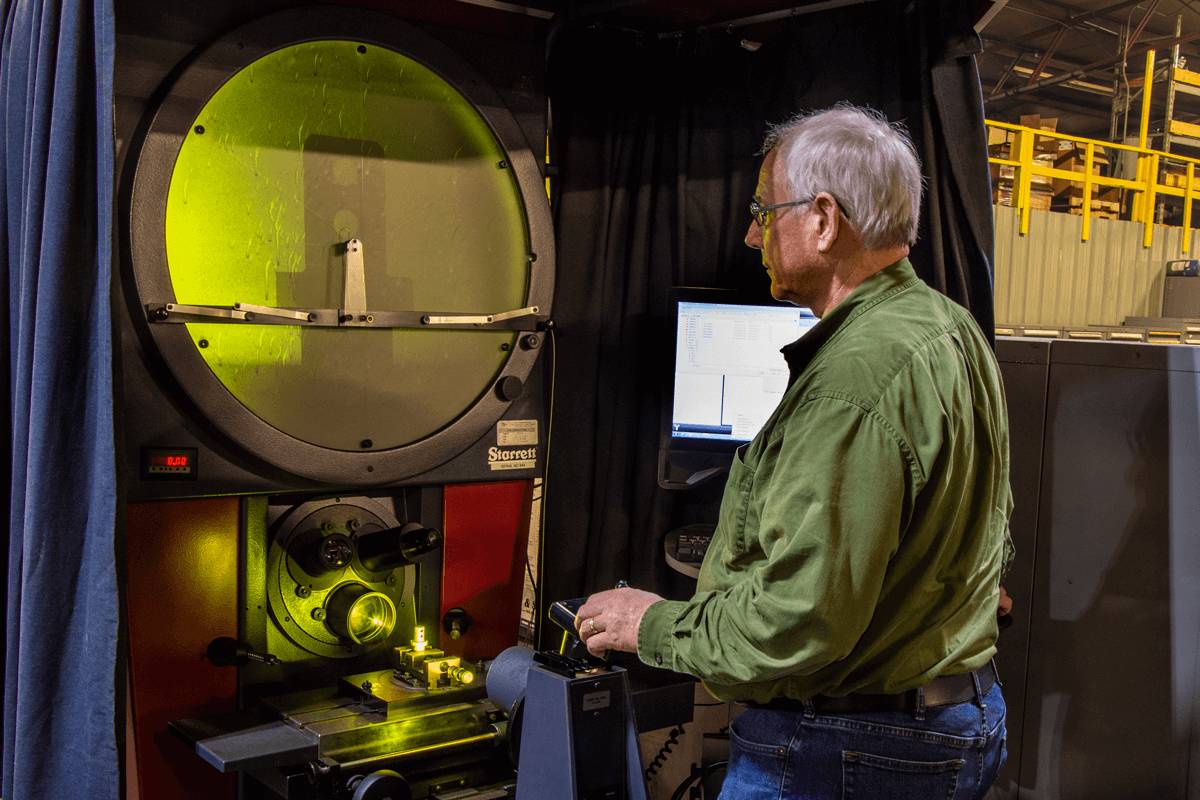

CAPABILITIES

Our goal, is to make it in house

A wide range of machinery at our disposal allows us to meet our customers’ needs, large or small. We have the ability to machine the tight tolerances required for our custom designed dampers. We are able to offer a completed damper starting from bar stock, castings or forgings, machined, inspected and assembled into finished dampers ready to ship. We can also offer secondary powder coated finishes for additional costs. Our goal, if at all possible, is to make it in house. Proudly made in America.

Engineering

EDS offers the best damper application experience in the industry. Our over 100 years of combined experience provides the knowledge and creativity needed to innovate specific product solutions to exceed customers’ expectations.

DAMPER DESIGN MODELING

Early collaboration is the key to long term success. EDS offers a variety of custom design options for demanding environments. Read More

DAMPER DESIGN TOOLS

EDS utilizes an assortment of CAE tools. We are capable of simulating and predicting detailed parameters of torsional damper development requirements. Read More

Quality

At EDS, we value our processes, where we are inspecting and gauging the parts to ensure a quality product is shipped to our customer.

At EDS, quality is working on the shop floor with our assembly associates using gauges or checking product quality with the CMM in our quality lab. Your company can rest assured that your products meet all standards of uniformity, consistency, and quality.